Science

Innovative Robot Technology Enhances Safety in Aircraft Assembly

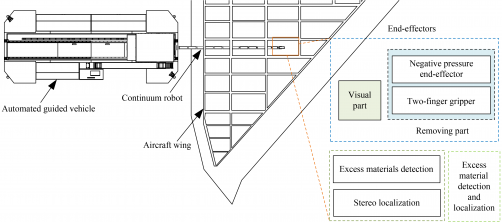

Excess materials such as nuts, rivets, and aluminum shavings left inside aircraft wings during assembly pose serious safety risks. These materials can disrupt the operation of vital components, potentially leading to flight accidents. Addressing this issue, a team from Beihang University has developed a research project titled “Detection and Removal of Excess Materials in Aircraft Wings Using Continuum Robot End-Effectors,” aimed at enhancing the efficiency and safety of aircraft assembly processes.

Advanced Robotics in Aircraft Maintenance

Traditionally, the inspection and removal of excess materials in aircraft wings rely heavily on manual operations. However, the confined spaces within aircraft wings make manual access challenging, and conventional robots often struggle in these complex environments. This limitation results in low removal efficiency, highlighting the need for innovative solutions.

The research team at Beihang University has introduced a continuum robot equipped with a specialized removal end-effector and a stereo camera. This technology is designed to effectively eliminate excess materials. Initially, the research focused on analyzing the size and weight characteristics of these materials to inform the design of two key end-effectors: a novel negative pressure end-effector and a two-finger gripper. The negative pressure end-effector is adept at removing small nuts, rivets, and aluminum shavings, while the two-finger gripper is intended for larger volumes of debris.

To tackle the issue of poor lighting conditions within the wing compartments, the researchers integrated supplementary lighting devices to enhance visibility during operation. This adaptation is crucial for ensuring accurate detection and removal of materials.

Effective Detection and Removal Techniques

The project employs the You Only Look Once (YOLO) v5 algorithm for the classification and detection of excess materials. The team constructed two training datasets specific to two types of aircraft wings, enabling the algorithm to perform efficiently. Given the limited texture features in the wing interiors, the researchers utilized an image-matching method based on the YOLO v5 detection results. This approach mitigates performance instability often encountered with traditional feature point matching techniques.

Experimental results indicate that the detection accuracy for each type of excess material exceeds 90%. Additionally, the visual localization error for four types of excess objects remains below 2 mm, validating the efficacy of the robot’s capabilities.

The two end-effectors have proven to be effective in completing the task of removing excess materials from aircraft wings, significantly improving operational safety in aircraft assembly. The findings of this study, authored by Xiujie CAO, Jingjun YU, Siqi TANG, Junhao SUI, and Xu PEI, are detailed in the paper titled “Detection and Removal of Excess Materials in Aircraft Wings Using Continuum Robot End-Effectors,” published in March 2024.

For further details, the full text of the paper is available at https://doi.org/10.1007/s11465-024-0806-2.

-

Lifestyle5 months ago

Lifestyle5 months agoLibraries Challenge Rising E-Book Costs Amid Growing Demand

-

Sports4 months ago

Sports4 months agoTyreek Hill Responds to Tua Tagovailoa’s Comments on Team Dynamics

-

Sports4 months ago

Sports4 months agoLiverpool Secures Agreement to Sign Young Striker Will Wright

-

Lifestyle4 months ago

Lifestyle4 months agoSave Your Split Tomatoes: Expert Tips for Gardeners

-

Lifestyle4 months ago

Lifestyle4 months agoPrincess Beatrice’s Daughter Athena Joins Siblings at London Parade

-

Science4 months ago

Science4 months agoSan Francisco Hosts Unique Contest to Identify “Performative Males”

-

World4 months ago

World4 months agoWinter Storms Lash New South Wales with Snow, Flood Risks

-

Science5 months ago

Science5 months agoTrump Administration Moves to Repeal Key Climate Regulation

-

Business5 months ago

Business5 months agoSoFi Technologies Shares Slip 2% Following Insider Stock Sale

-

Science5 months ago

Science5 months agoNew Tool Reveals Link Between Horse Coat Condition and Parasites

-

Sports5 months ago

Sports5 months agoElon Musk Sculpture Travels From Utah to Yosemite National Park

-

Science5 months ago

Science5 months agoNew Study Confirms Humans Transported Stonehenge Bluestones